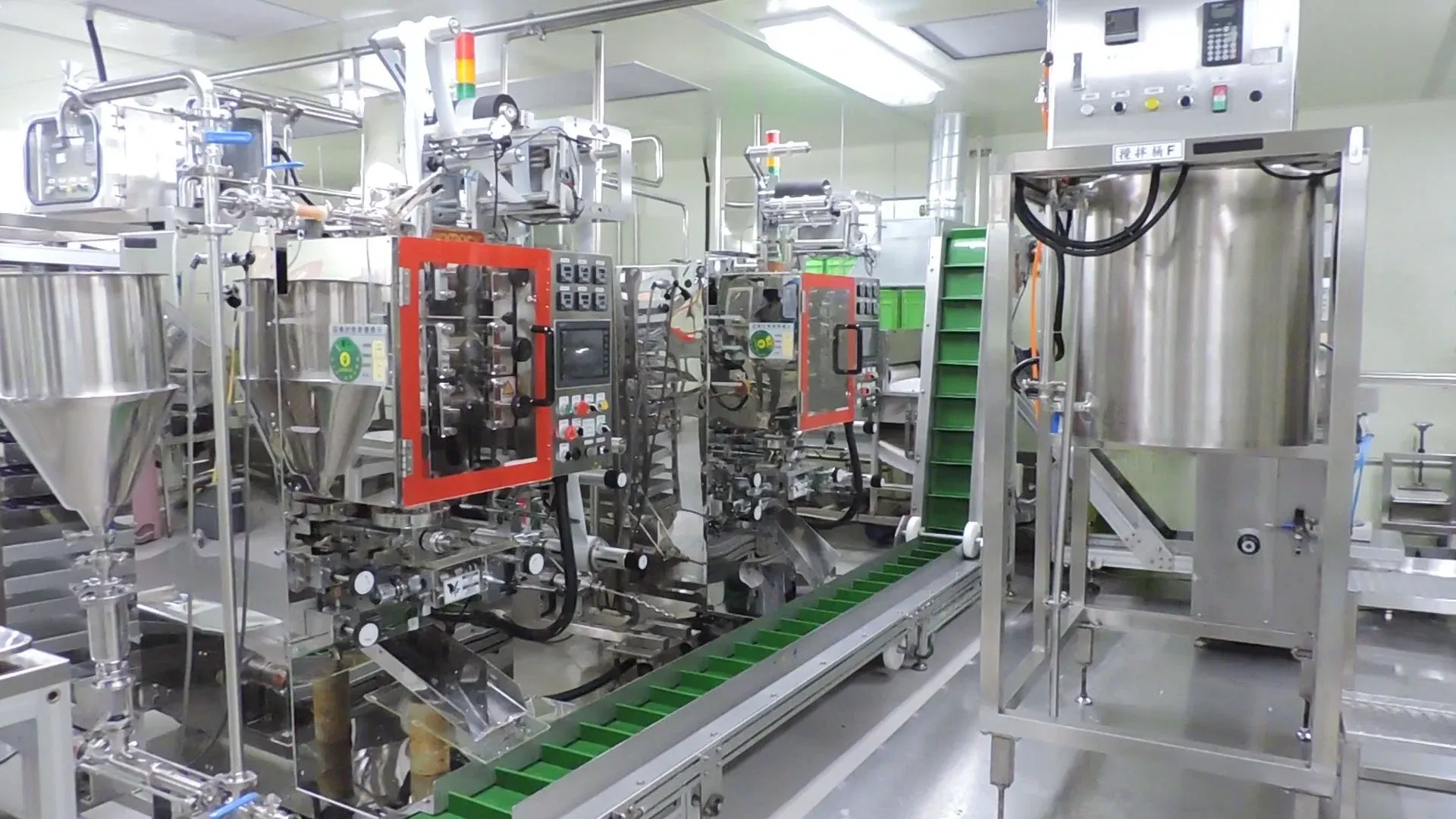

Factory

High-Quality Controlled Supplement Factory

We build our standardized production process upon globally recognized certifications to ensure consistency in every steps. It’s our commitment to turning your innovative ideas into reality.

360° Virtual Factory Tour

Immersive Factory Tour at Your Fingertips!

Interested in an in-person visit? We’d love to hear from you.

8 Steps of Quality Control Procedures to Reach the Highest Standard

From raw materials to finished products, our facility follows a thorough inspection process covering water systems, air quality, hygiene, production, packaging, and shipping, ensuring product safety and consistent quality through 843 inspection items.

Raw materials evaluation

Water activity monitor

Environment quality

Process requirements

Safety management

Shelf-life examination

Standard requirements of finished product

OQC control

Quality Control Process

Environmental Quality

Water System

- Microbiological Parameters (Total Bacterial Count, Escherichia coli, Coliform Bacteria)

- TDS(<500 mg/L)

- pH (6.0-8.5)

- Free Residual Chlorine(0.2-1.0mg/L)

HVAC System

- Airflow Direction (Pressure Differential) Monitoring

- Air Change Rate Monitoring

- Particle Count Monitoring

Hygiene and Safety

Environmental Cleanliness

- Temperature and Humidity Monitoring

- Microbiological Parameters (Total Bacterial Count, Mold/Yeast, Staphylococcus aureus, Salmonella spp.)

Personnel Hygiene

- Microbiological Parameters (Total Bacterial Count, Escherichia coli, Coliform Bacteria, Staphylococcus aureus)

Incoming Material Inspection

Raw Materials

- Microbiological Testing (Total Bacterial Count, Escherichia coli, Coliform Bacteria, Mold, Yeast)

- Chemical Analysis (380 Pesticide Residues, Heavy Metals, Sulfur Dioxide, Material Composition and Migration Testing)

- Physical Testing (Thickness Measurement)

- pH

- Brix

- Moisture Content

In-Process Inspection

Manufacturing Process

- Sterilization Vessel Temperature and Time Monitoring

- pH

- Brix

- Moisture Content

- Seal Integrity Testing (Light Transmission Inspection, Pressure Resistance Test)

- Microbiological Testing (3 Parameters)

- Weight Inspection

In-Process Materials

- Microbiological Testing (Total Bacterial Count, Escherichia coli, Coliform Bacteria, Mold, Yeast, Salmonella spp.)

- Chemical Analysis (380 Pesticide Residues, Heavy Metals, 5 Preservatives, 9 Plasticizers, 8 Food Colorants)

- Physical Testing (Matching Test, Moisture Content)

- pH

- Brix

- Active Ingredient Content

Finished Product Inspection

Final Packaging

- Appearance Verification (5 Criteria)

- Quantity Verification

- Date Labeling Check

- Metal Detector Inspection

- Weight Checker Inspection

Stability Testing

- Microbiological Testing

- Visual Appearance

- pH

- Brix

Pre-Shipment Inspection

Shipment Inspection

- Verification of Shipment Quantity

- Verification of Contents and Labeling

Medical-Grade Raw Material Testing

Wel-Bloom applies its expertise in health and medical-grade ingredient trade to ensure strict quality control of all raw materials, including COA verification and microbiological tests (total plate count, mold & yeast, E. coli, coliforms). Materials may also undergo re-inspection or random testing at customs storage. Final products are tested by SGS for pesticides, plasticizers, and maleic acid—all with non-detectable results.

News & Updates

Wel-Bloom Bio-Tech

Leader of Jelly Supplement

-

Phone +886-2-33225555

-

Fax +886-2-3322-5966

-

Email service@welbloom.com.tw

-

LINE Official Account @welbloom

-

LinkedIn Welbloom BioTech

Contact Us

We will reply them as soon as possible.